-

메일로 보내주세요 : sales09@zwwheels.com

-

전화주세요 : +86 (0)25 84725893

무엇을 찾고 계신가요?

무엇을 찾고 계신가요?

메일로 보내주세요 : sales09@zwwheels.com

전화주세요 : +86 (0)25 84725893

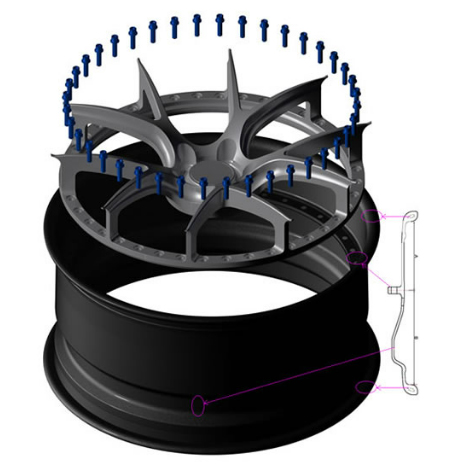

A two-piece forged wheel is a high-performance modular wheel constructed from two separate components: a center face (spokes and hub) and an outer barrel (rim). These components are typically manufactured from high-grade 6061-T6 aluminum using extreme heat and pressure to align the metal's grain structure, resulting in superior strength and lightweight characteristics compared to standard cast wheels.

Construction and Components

Center Section (Face): Machined from a solid forged aluminum billet, this part houses the spokes and mounting surface.

Outer Barrel: A separately manufactured cylindrical piece that holds the tire in place.

Assembly Methods: The two pieces are permanently or semi-permanently joined through welding (creating a unified, rigid structure) or bolting with high-strength hardware.

Key Benefits

Customization: Modular construction allows for a wider range of offsets, widths, and finishes than one-piece (monoblock) wheels. For instance, a customer can choose a custom-colored center with a polished or chrome barrel.

Repairability: If a wheel is damaged by a pothole or curb, the affected component (the barrel or the face) can often be replaced independently, saving up to 40% in total replacement costs compared to a one-piece wheel.

Performance: Forged 2-piece wheels are roughly 20–30% lighter than cast wheels, reducing unsprung mass to improve acceleration, braking distances, and handling agility.

Maintenance: They generally require less upkeep than 3-piece wheels because they have fewer joining points and seals to monitor.

Hi! Click one of our members below to chat on